To ensure accurate MTF measurements, it is important to select the correct test chart size and resolution. It is also crucial for chart resolution to exceed the resolution of the sensor by a significant margin so the imaging system rather than the chart is measured.

Various materials and printing processes provide different printed resolutions, and Imatest uses an array of technologies to suit every application. Listed below is a list of materials that we offer and the resolution differences among them.

Note: See Test chart suitability for MTF measurements for additional information; see Chart MTF Compensation for further details on the calculations and how a lesser-quality chart can be compensated.

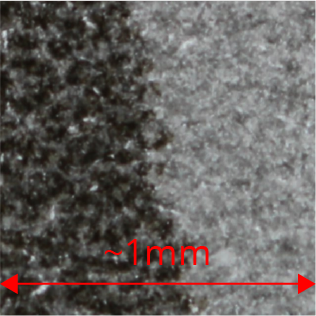

Inkjet |

targets (also called "charts") are the lowest resolution material that Imatest offers, but the least expensive and most versatile. |

Inkjet |

targets are ideally suited for cameras tested at a moderate distance to compensate for the |

low resolution of the prints. As the |

resolution is relatively low, the size of |

each chart needs to be larger to accommodate a higher resolution sensor. The Inkjet target is also suitable for low-resolution or wide-angle systems. Inkjet targets are available in three substrates: Matte and Semigloss for reflective testing and DisplayTrans for transmissive tests using a backlight. All inkjet options are roughly the same resolution. The minimum print size of the Imatest inkjet target is approximately 8” x 10”; maximum print size is 44” x 80”. | Inkjet - Matt, Semigloss, |

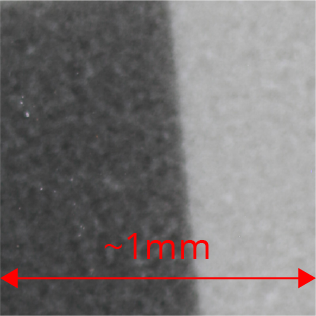

Photographic targets offer high-resolution reflective prints when transmissive targets are not an option. These prints are over twice the resolution of inkjet media. Our standard photographic targets include the eSFR ISO chart (in three sizes) and a multi-size option of the SFRplus chart. The multi-size target is best suited for testing low-resolution systems at close distances. |

The minimum size of a photographic print is approximately 8” x 10”; maximum size is approximately 40” x 50”. We offer custom charts on this media for an additional fee; contactcharts@imatest.com for information. | Photographic Paper |

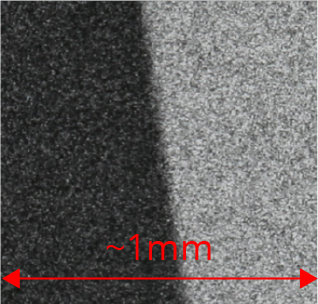

Black and white film is over twice the resolution of our inkjet targets and can include a color patch for color measurements. This media is ideal for customers testing in a small area with low-to-medium resolution cameras. We can print multiple targets on a single sheet of film, depending on the size and resolution requirements |

. The size of the film is 12” x 20” or 16” x 20” (with a 0. |

5-inch unprintable area on each side |

); the minimum target size |

is roughly 2” x 3”. For high-resolution systems, we can tile together multiple pieces of LVT film to fit the size of your lightbox. This option is |

ideally suited for customers testing high-resolution cameras such as DSLR’s. The maximum dimensions using this option are approximately 19” x 32”. | Black and White LVT Film |

High-precision color film is suited for customers requiring a very compact testing system or those using conversion optics to simulate infinity within a small space. The fine detail of |

this film allows us to test mid- to high-resolution cameras at close distances and with a small field of view. Color film has the highest dynamic range of all of the targets we offer. High-precision color file targets are printed on 8” x 10” film with a maximum printed area of 9.25” x 7.75”. The minimum target size on this media is approximately 0.5” x 1”. As with the Black and White film, we can print multiple targets to a single sheet of film to make this a cost-effective option. | Color LVT Film |

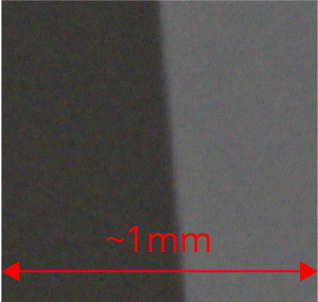

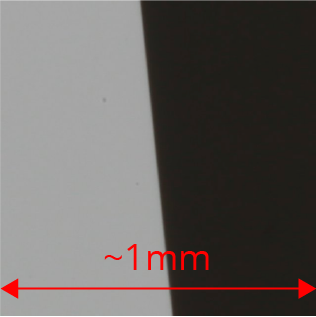

Chrome Photomasks are our sharpest option for resolution testing. We use a lithographic photomasking process to print chrome directly onto glass. |

Chrome on Glass offers superior resolution when color and tonal measurements are not needed; this process is single-tone, so there is no gray-scale or tonal variance. |

We can make targets as small as 2mm x 3mm for measuring devices such as endoscopes or microscopy equipment. When printing to glass, the chrome has an optical density of 1, which gives a contrast ratio of approximately 10:1, suitable for resolution measurement. Our standard glass plates are 4” x 4” with a non-printable border of 1 cm. We can source plates up to 20” x 20” and as small as 1” x 1”. Any plates larger than 4” x 4” require an extended lead time of 6 to 8 weeks. | Chrome on Glass Photomask |